Better butter: California is the cream of the crop

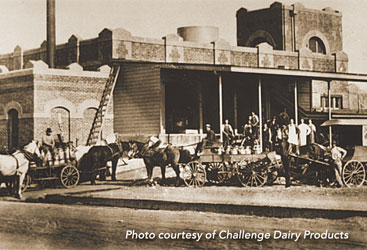

The early days of California butter production, circa 1900.

Butter is the stuff of legends. It's said that the product originated when a traveler transporting a container of fresh milk happened to churn the cream into butter with each step. While the exact year of such a discovery isn't known, records show that butter has been around for thousands of years but didn't become commercially available until the early 1900s. One thing is for sure—California has been on the butter bandwagon ever since.

Today the Golden State is the leading butter producer in the country, churning out more than 500 million pounds a year, according to Irvin Holmes. And he should know: Holmes is CEO of Dublin-based Challenge Dairy Products Inc., one of the first and the largest butter brand in the West.

Challenge Butter got its start 100 years ago in the town of Tulare when three representatives from the Dairyman's Cooperative Creamery Association organized a marketing group to promote their farm-fresh product.

Their majestic elk logo has been around since then too. History says a general manager was inspired by an elk mural at a tavern with the word "Challenge" under it. The founders were challenging themselves and other dairy organizations—and the elk stuck.

"It's bright and distinctive in a category when you are used to seeing a cow in a green pasture," Holmes explained, laughing.

Stephen Maddox, left, and son Stephen Jr. stand proudly with prize-winner Constance, one of 4,100 Holstein cows milked three times a day at the family’s dairy in Riverdale.

In the beginning, the association rented a storeroom in Los Angeles and started peddling its product. "The new company had four employees and a wagon, but had to rent a horse to pull it," Holmes said.

Times have changed, but the cooperative spirit hasn't. Today Challenge and California Dairies Inc. is owned by more than 500 California dairy farmers. The milk for Challenge Butter originates on family farms from San Diego County to Marin County, with most in the San Joaquin Valley.

"We're a co-op," Holmes said. "We're owned by the farmer, we're employed by the farmer. We're proud of that fact."

Stephen Maddox is one of those farmer-owners. Maddox Dairy in Riverdale, 35 miles from Challenge's Fresno plant, has been providing milk to the cooperative since the mid-1960s.

Maddox Dairy is a family affair. Stephen Maddox, the managing partner of the dairy since its inception, started alongside father Doug Maddox, and now son Stephen Jr. is active in the family business as a dairy manager.

Milk from the farm is delivered to Challenge Butter’s plant in Fresno. More than 100 tankers come through the facility every day.

Maddox Dairy adheres to high standards when it comes to milk production. The 4,100 Holstein cows are milked three times a day, and Stephen Maddox points out that great butter starts with a well-managed dairy.

"The best-quality milk makes the best-quality butter," he said. "You've got to realize these are my babies. The more you pamper them, the better they produce." That pampering comes in many forms, starting with how the cows are fed.

"We make sure they are getting enough fiber, protein and energy," he explained.

Much of what the Holsteins eat, such as alfalfa hay or corn silage, is grown on the farm. Twice a month, a nutritionist checks to make sure the diet is meeting the cows' needs.

"I have a similar education in nutrition, so I can check their weight daily and make sure they have a nutrient-balanced diet," said Maddox, who graduated from Cal Poly, San Luis Obispo, with a degree in dairy science.

This attention to detail is rewarded. For instance, Constance, a prized red cow on the Maddox Dairy, won Reserve All-California 5-Year-Old at the 2010 California State Holstein Show in Merced.

Every day, more than 100 tankers pick up milk from farms like the Maddox family's and deliver it to the Challenge plant in Fresno. After a quality-control and safety check, the butter-making process begins.

It takes about 2 1/2 gallons of whole milk to make one pound (four sticks) of butter. First the cream is separated from the milk and then pasteurized. After a holding and cooling period to crystallize the butter fat, the churning begins.

"Our butter is churned daily," Holmes said. Churning, in simple terms, is the physical agitation of the cream. Butter is separated from the buttermilk and then worked into the desired texture—creamy and rich for regular butter and smooth, creamy and rich for Challenge's spreadable brand.

"There's nothing like taking fresh butter from the churn," said Maddox, who as a Challenge board member for 16 years visited the plant every other month. "It's like cream cheese."

Speaking of taste, when it comes to holiday baking, butter is the real star of the show.

"The six-week Thanksgiving and Christmas period represents a quarter of all retail and grocery butter sales," Holmes said.

Karen Holmes knows something about holiday baking. The baker and owner of Karen's Bakery Café and Catering in Folsom—in the foothills just outside Sacramento—was influenced by her Danish mother.

"We were the house growing up that around the holidays always had 10 to 12 types of cookies," she said. "There was always baking going on."

Holmes (no relation to Challenge's Holmes) has been baking since she could read a cookbook, and she and her team today create nearly 7,000 baked goods a month. Virtually all of her products contain butter.

"A baker without butter is like a bank without money. It's the foundation of everything," she insisted, adding that quality is crucial. "Our dairy purveyor is one of the most important relationships we have here, and we really value the fact that we can count on our dairy guy and that the dairy products we are getting are consistent, that they are reliable."

A peek inside the bakery's walk-in refrigerator shows rows of Challenge Butter waiting to be put to use.

"Butter provides so much for a recipe—moisture, flavor, emulsion," she said. "The other ingredients ride on butter."

But with all the emphasis on eating right and low-fat options these days, how does butter fit into the equation?

Interestingly, retail butter consumption has steadily gone up year to year. The folks at Challenge aren't surprised, and they reference the farm-to-fork phenomenon as part of the reason.

"Butter is as simple as it gets," said Irvin Holmes, describing the product's growing appeal. Baker Karen Holmes puts it another way: "It's only now that science and the media have caught up. 'Don't eat anything you can't pronounce,' we are being told, and butter was there all along."

Jennifer Harrison is a reporter in Davis. She can be reached at info@california country.org.

Karen's baking tips

Karen Holmes (in black chef’s jacket) and her team, including Whitney Jeary, Maribel Alvarez and Emily Pille, rely on butter to create nearly 7,000 baked goods each month.

"How do you get your cookies so puffy?" is the top customer question at Karen's Bakery Café and Catering. The answer: It's all in the butter. Want your baked goods to be holiday hits? Follow baker Karen Holmes' tips:

- Avoid over-beating or over-mixing: Here is where puffy cookies come in. "Over-mixed dough spreads like pancakes," cautioned Holmes. To achieve height and puffiness when making cookies, cream the butter and sugar then add the dry ingredients, but mix only to the point where the dry ingredients just begin to disappear.

- Use unsalted butter: This enables you to control the amount of salt in the recipe. Salted butter may exceed the amount of salt the recipe needs and therefore throw off the flavor of your baked goods.

- Take the temperature: Butter should be at room temperature, but not too warm. You should be able to put a slight dent in it with your finger, but not sink your finger all the way through. "If it feels and looks too greasy, it will separate and not work in the recipe," Holmes explained.